Our Services

ECT provides a vast range of services for

Semiconductor Vaccum & Plasma Systems.

explore our services

ECT provides a varied range of services

related to Semiconductor vacuum and Plasma Systems.

Service Contracts

Critical equipment, whether for Development Projects or Front-Line Manufacturing, may profit from a Yearly Service Contract from ECT. We perform a Quarterly Preventative Maintenance visit, including electronic calibrations, replacing any worn Consumable items and baselining the system with an Acceptance Test Procedure (ATP).

If we find serious issues, the Service Contract would allow us to fix the problem by offering a 50% Discount from Retail on any parts, and 25% Discount on Service Engineer’s rate. A Great Deal… Call us for details

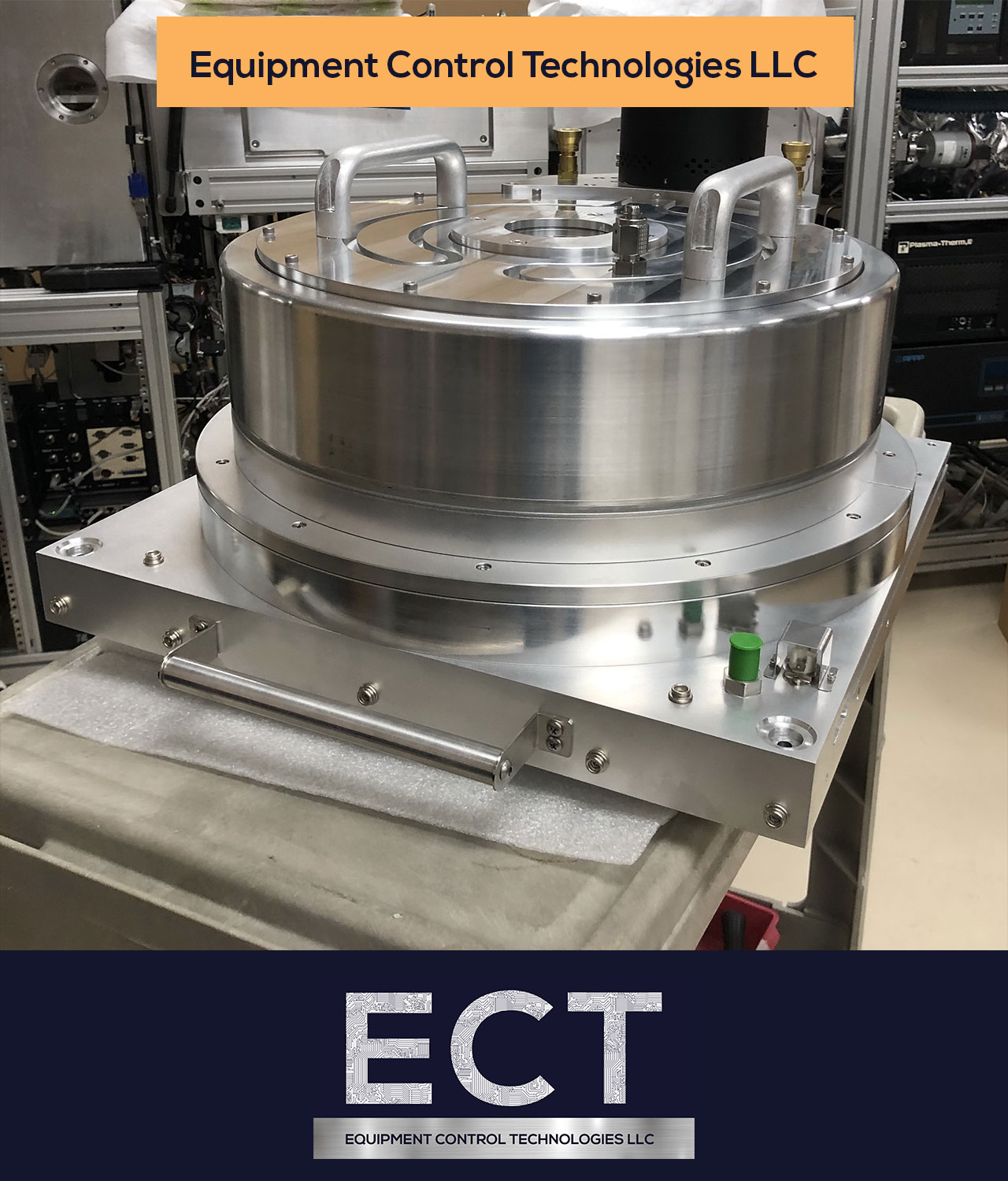

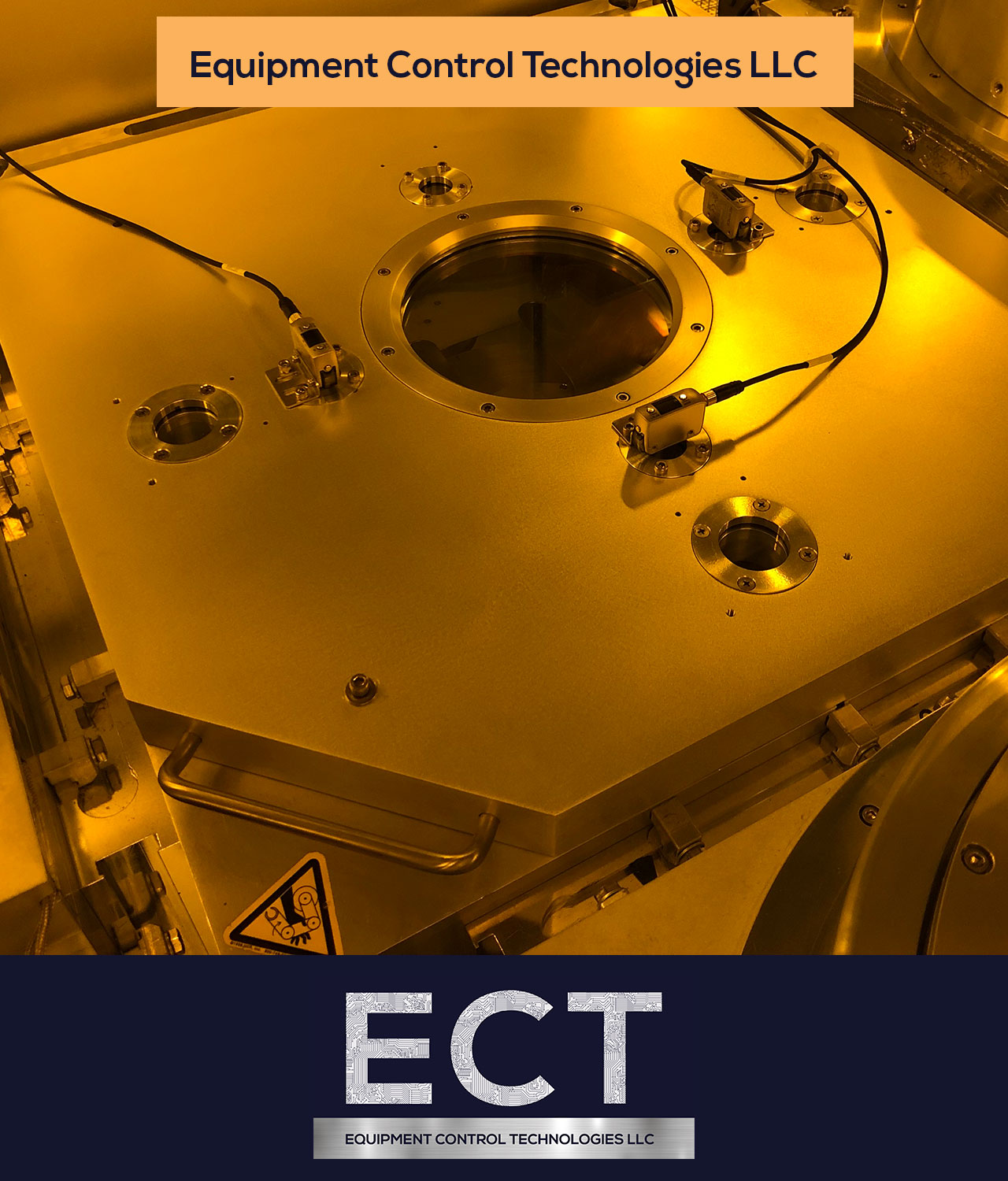

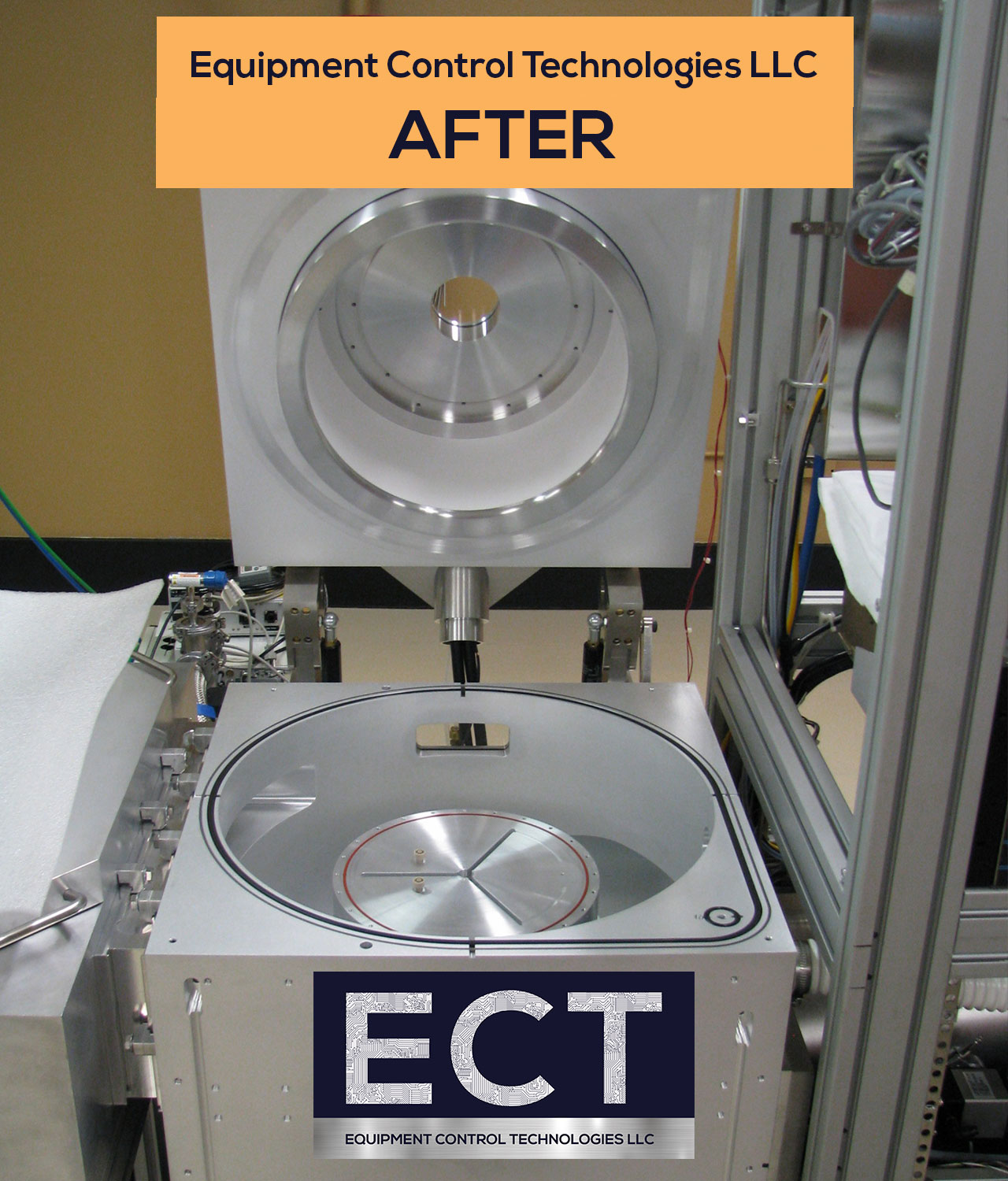

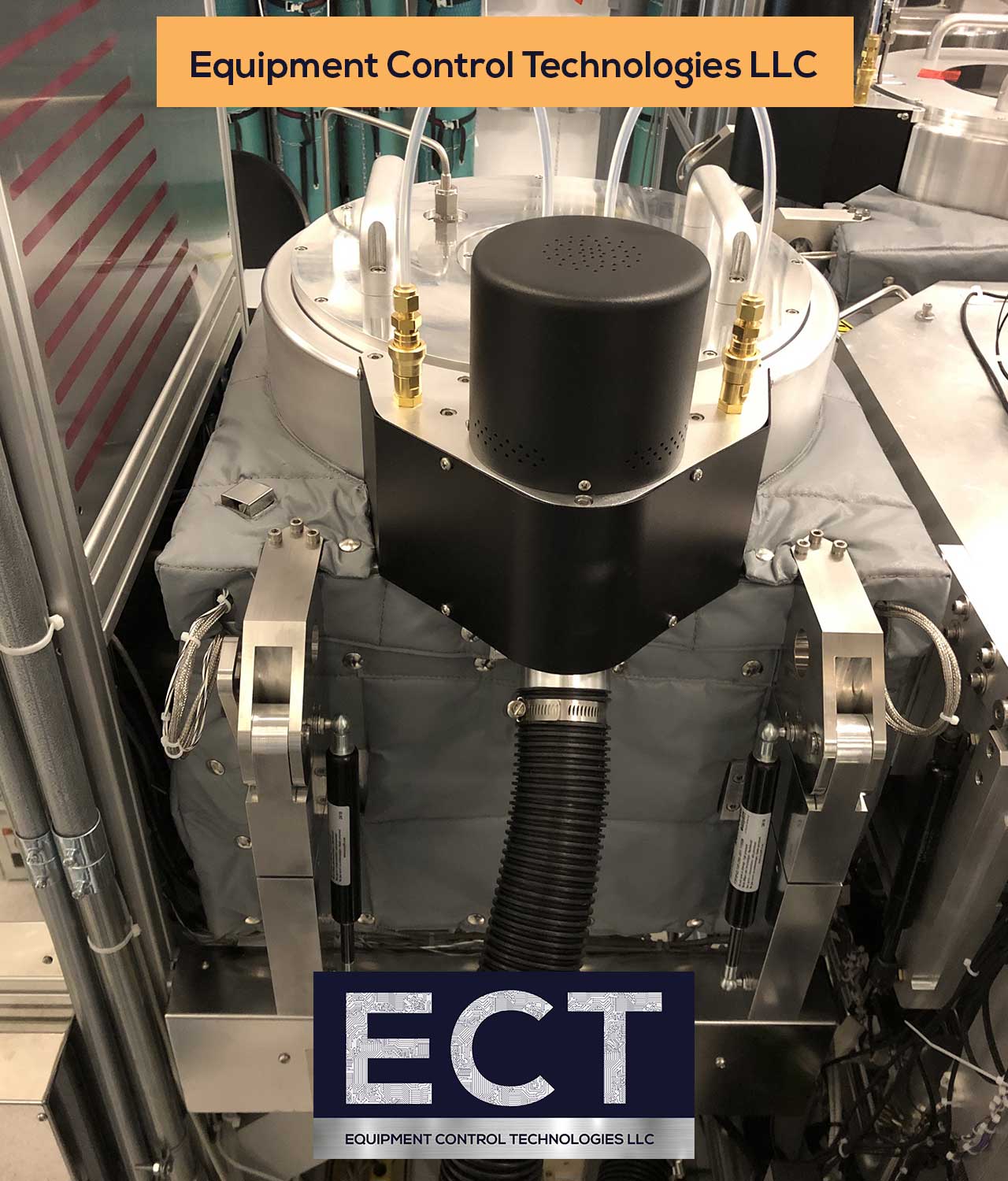

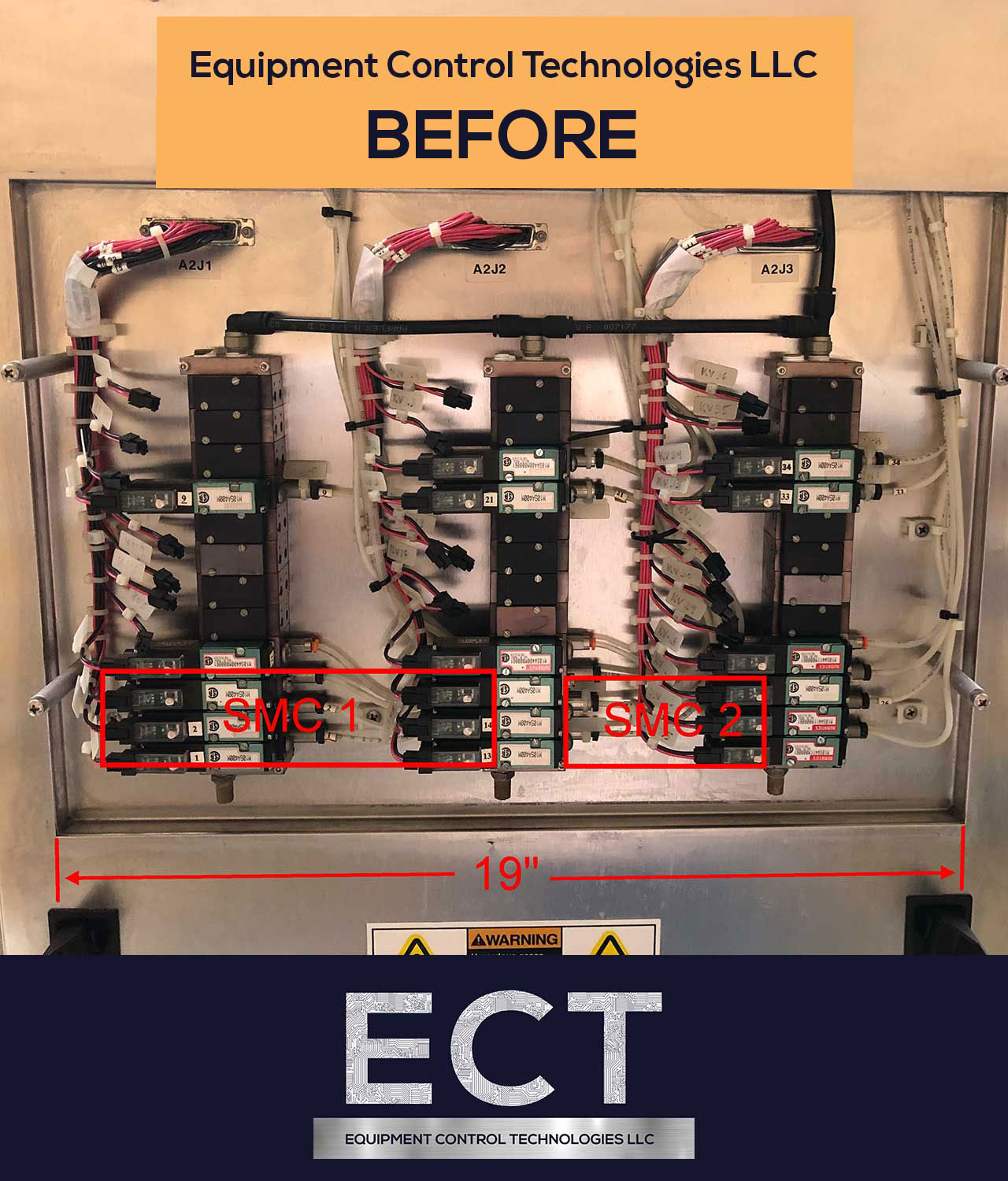

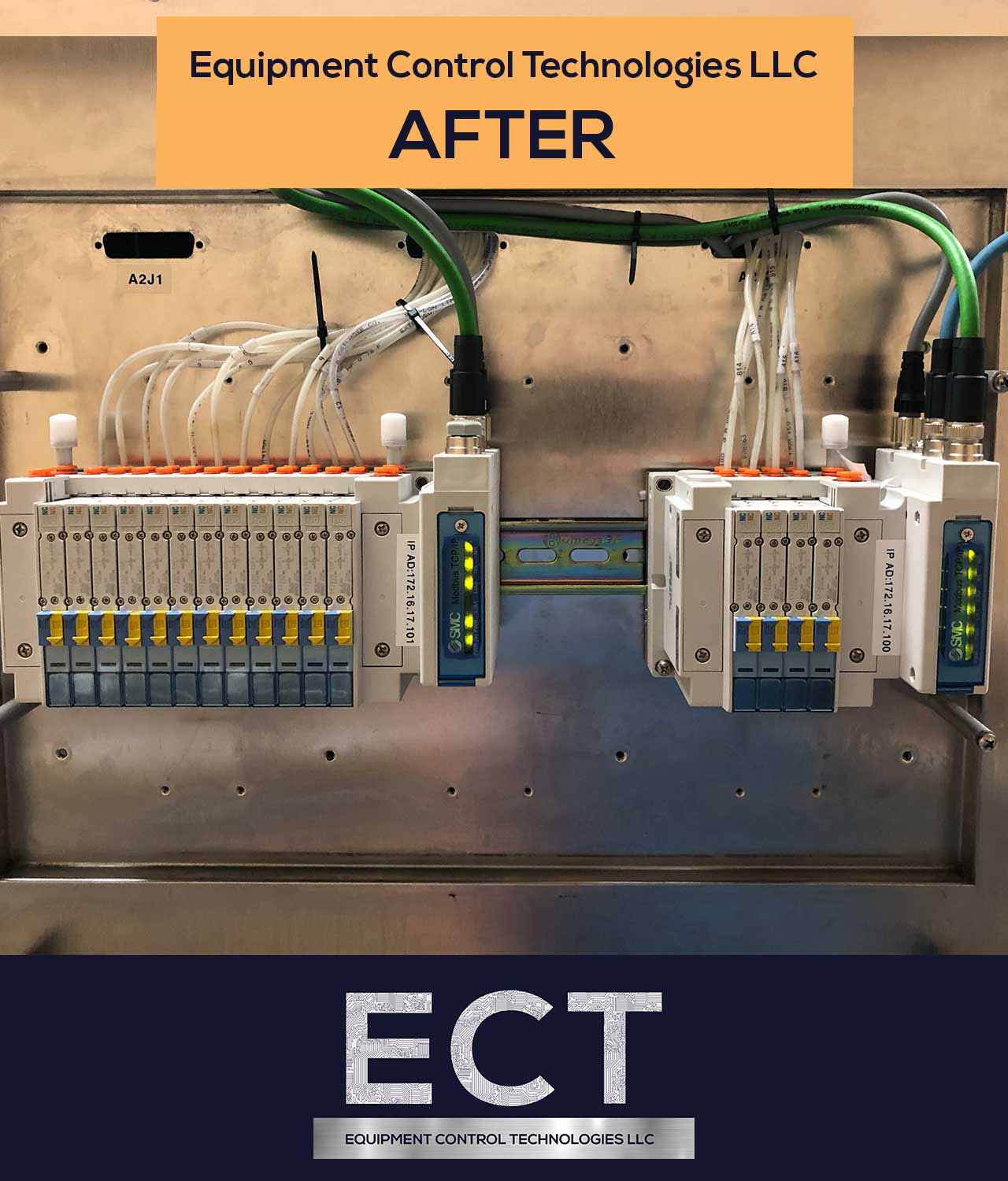

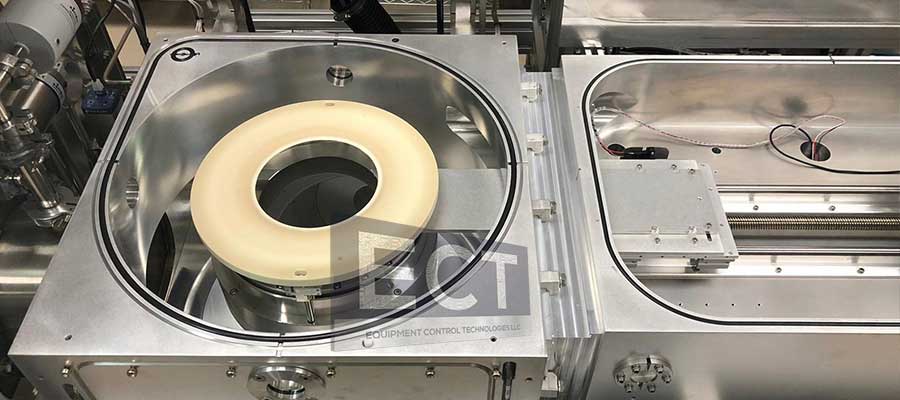

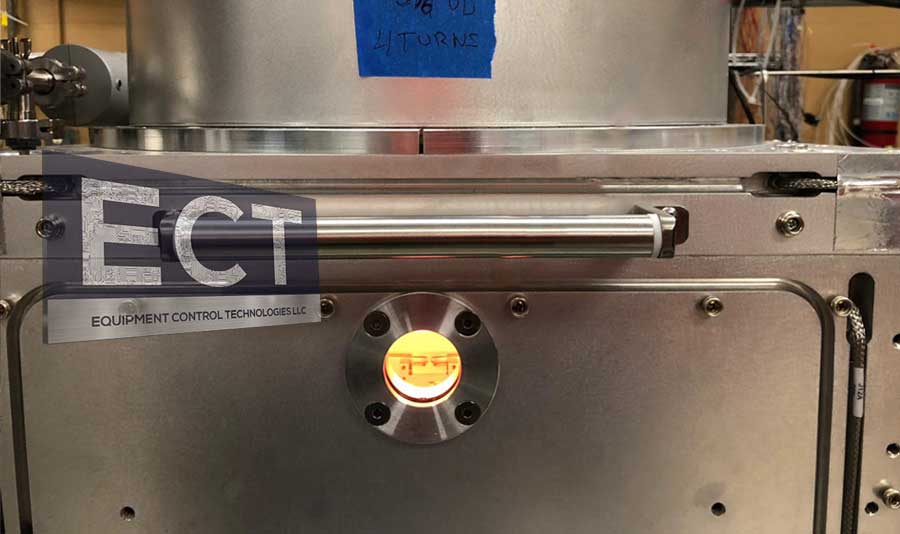

Equipment Upgrades & Refurbishment

ECT will perform upgrades to the systems that it refurbishes by replacing those that are obsolete and no longer supported by the OEM. Oftentimes we will upgrade the systems with a better hardware designs that aid the End-User with their maintenance activities and/or process improvements. We upgrade tooling in the field or at the factory at the request of its customers.

Click on any image below to see Equipment Upgrade & Refurbishment Work

Spare & Replacement Parts

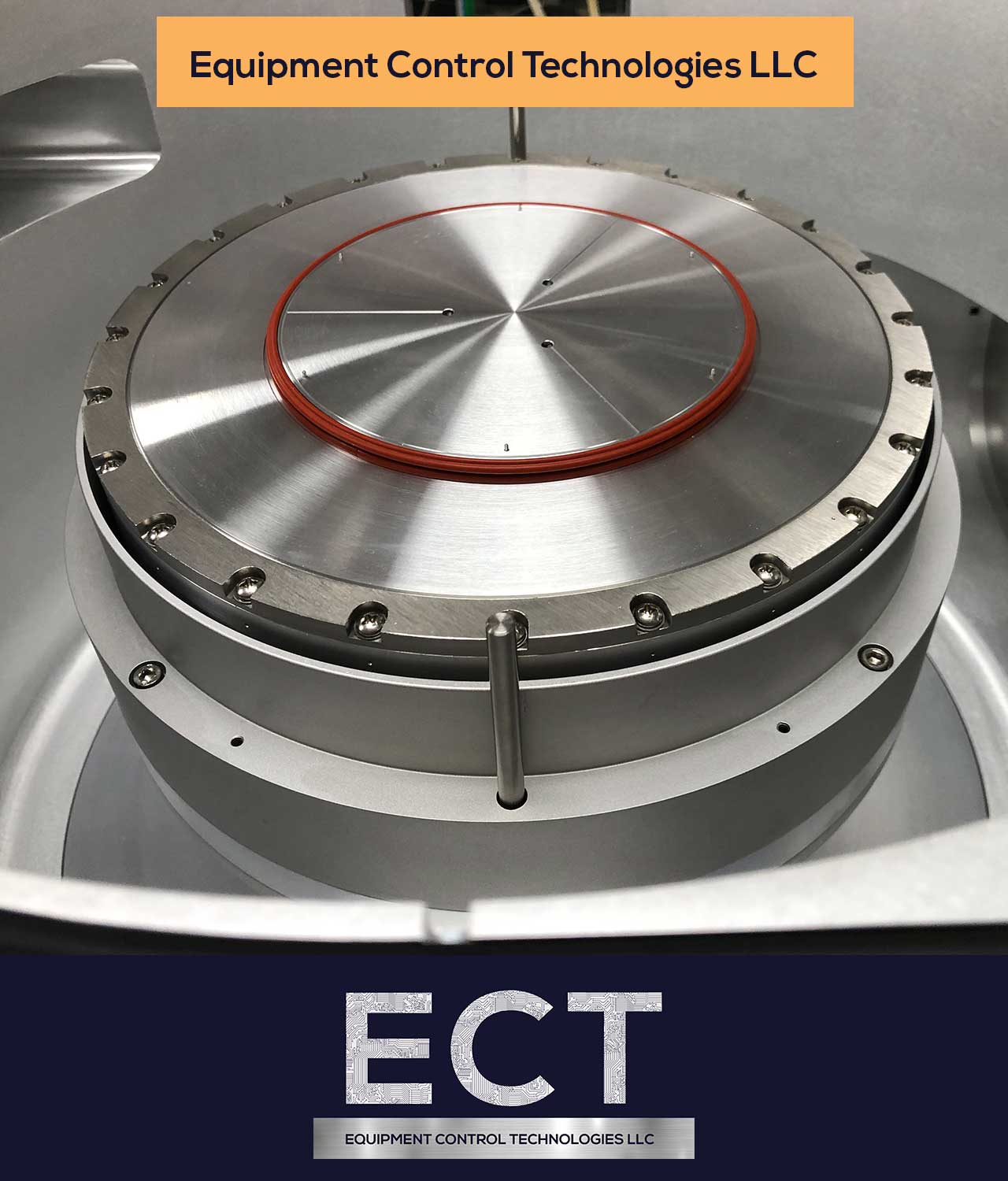

ECT will provide quotations for spare parts on all systems sold at the request of its customers. Many times at the request of customers we will manufacture brand new parts that serve as a direct replacement to the OEM parts, saving our customers money & time.

Field Service Support for Hardware & Process Engineering

ECT will support all its customers with Filed Service Support for any hardware and/or process issue. Process Support is where ECT has an advantage over simple System Resellers that only sell you a piece of equipment. ECT will sell you a Solution to a Technical need. We have both Equipment Experts and Plasma Process Experts as part of our Team, so the nuances between a Process result and the Equipment hardware are considered together, just like on your Fab floor. Process Support is organically bundled together with Equipment Support so that the End-User will have a single call to make for any questions on equipment problems, process issues, or advice on process improvements.

Technical Support

Secure Remote Hardware & Process Engineering Diagnostics: ECT considers after sale Technical Support to be as important as the Hardware being sold… Our Technical Support Team understand that plasma reactors are complex, so we initially diagnose any issues as being within the main areas of System Support (the Machine isn’t working properly) or Process Support (the result on the Wafer isn’t what’s desired). ECT has the capability to access every system that it sales remotely and securely without jeopardizing or invading the customers own computer network. Every system that we sale is shipped with specialized hardware that permits access to the system by the customer when needed. It allows our Experts to control and see firsthand how the System is responding to known commands and process conditions. This is a very powerful tool to diagnose issues in real-time, getting you back up and running quickly!

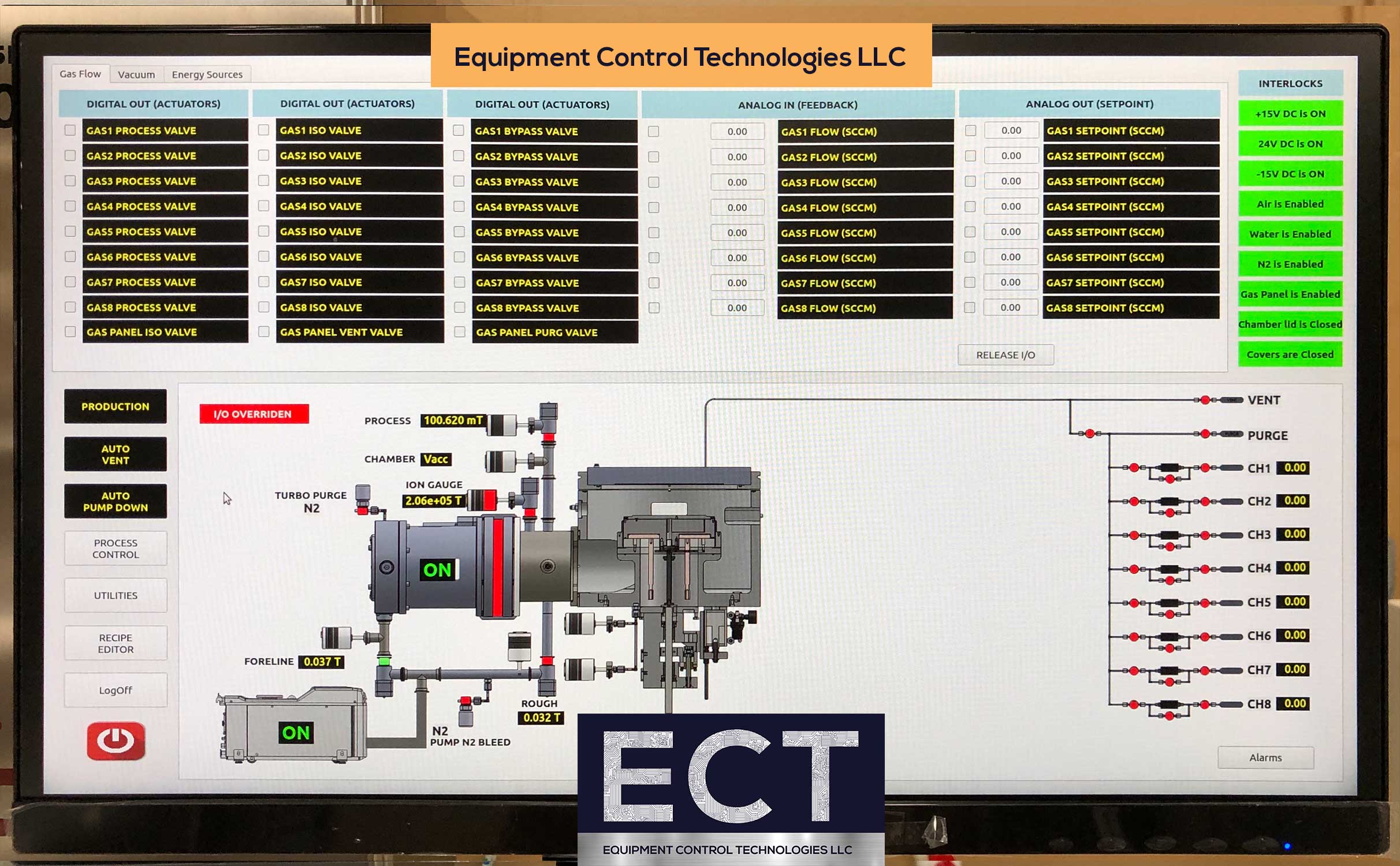

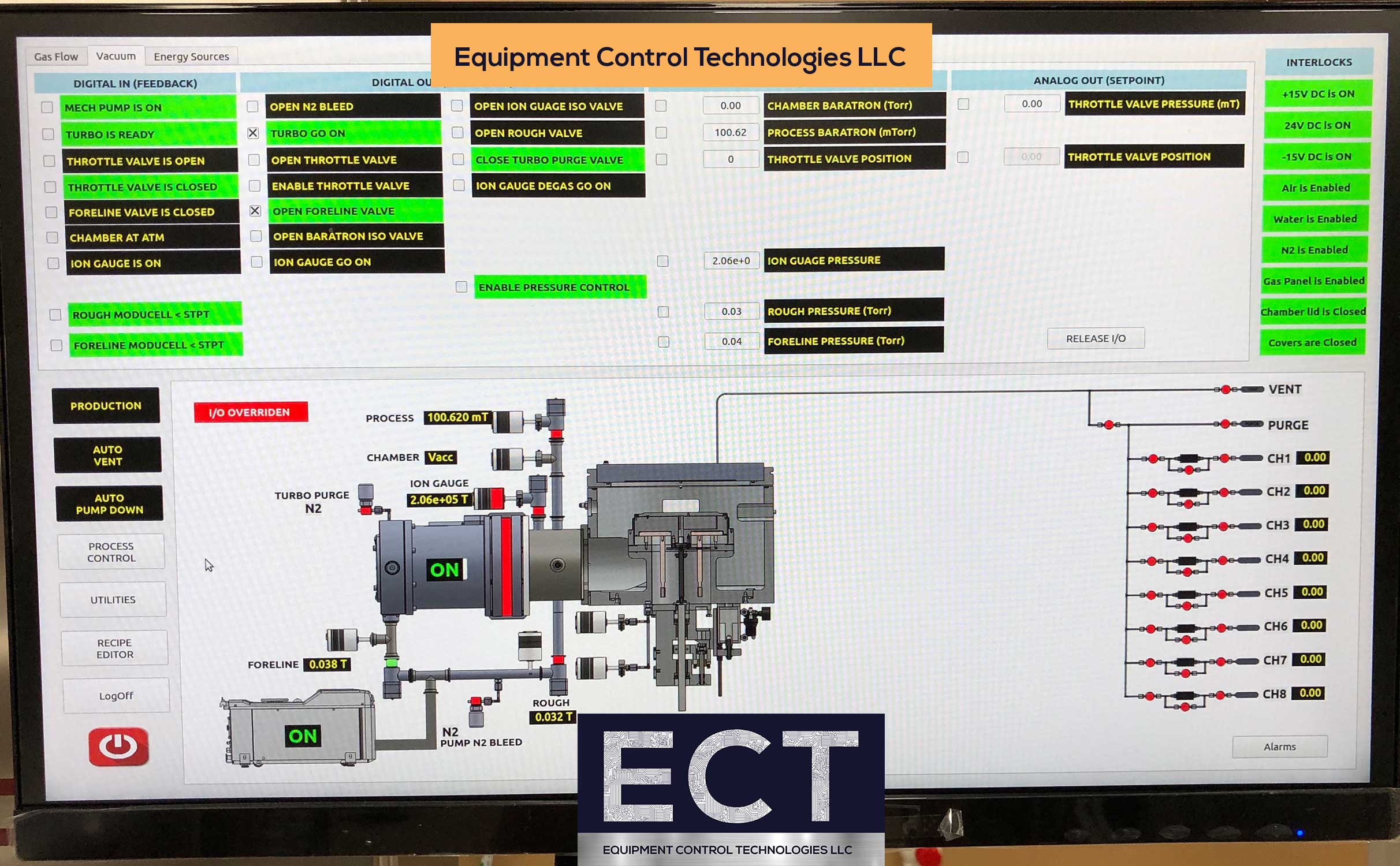

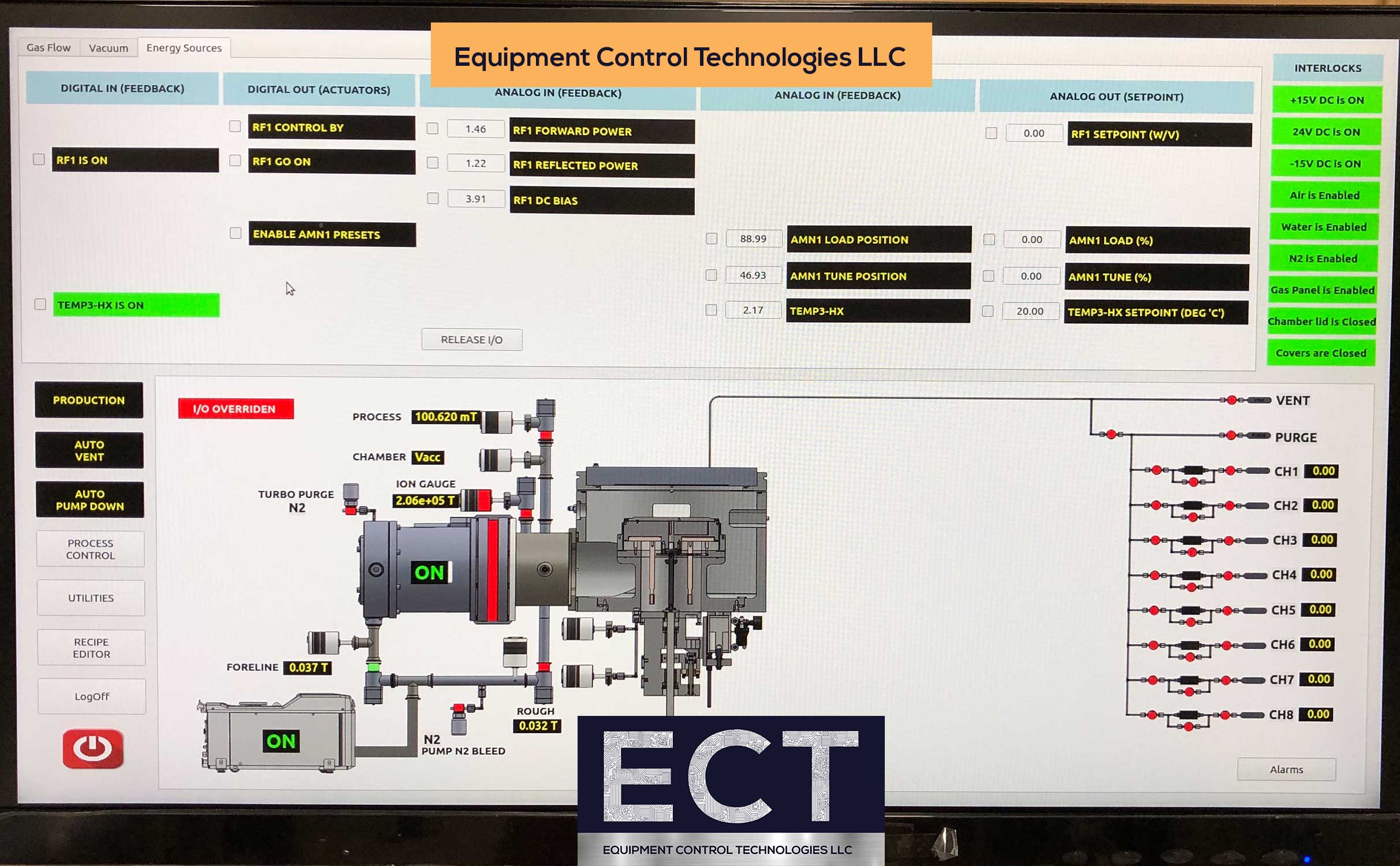

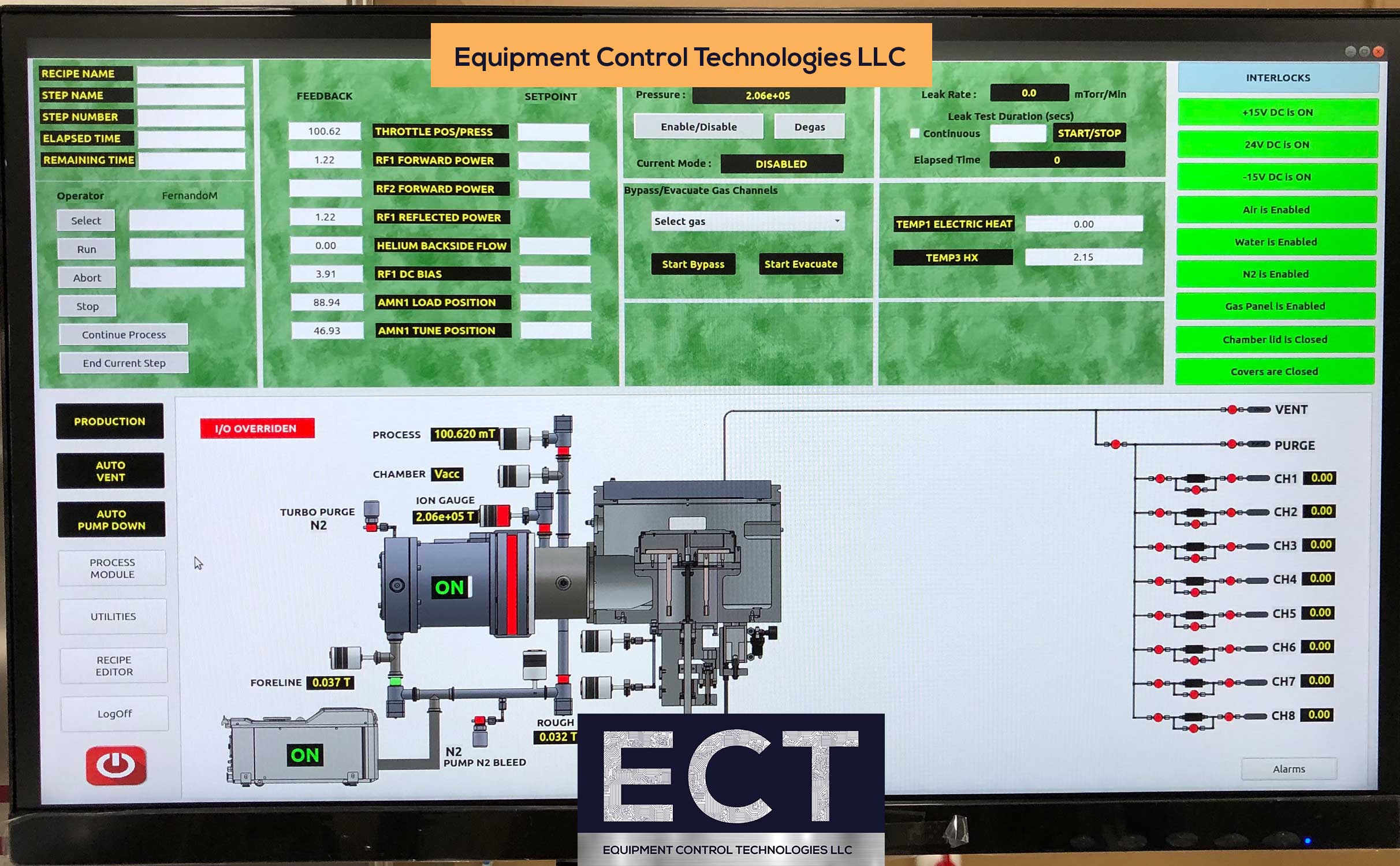

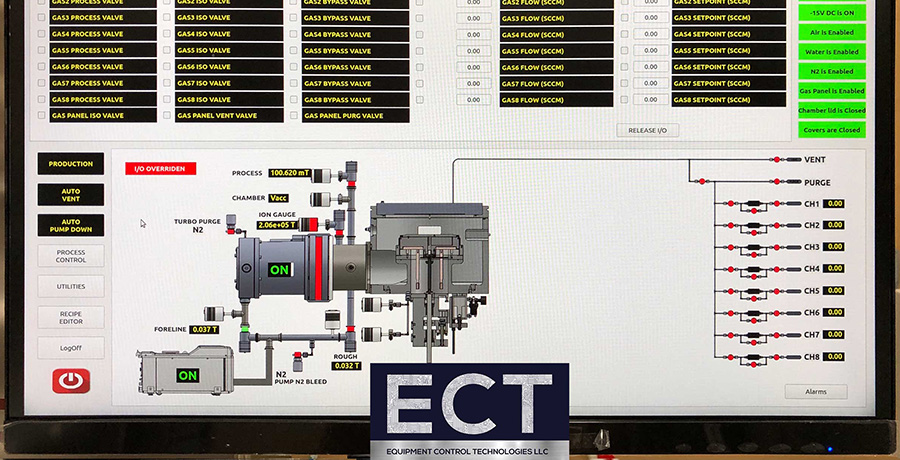

Control Systems

ECT has worked diligently for the past three years developing a new Control System called Equipment-Works (trademark). It has been developed with the intension of replacing the Old & Obsolete controls that are no longer supported by many of the OEM companies. The replacement automatically extends the life of many of these OEM systems with modern off the shelf hardware and a new state of the art industrial PC. The software has been designed to operate with BECKHOFF remote ethernet I/O and SMC Pneumatic Controls modules using the Modbus TCP/IP communications protocol. The new control system can be adapted to most dry etch system with minimal effort and at a very reasonable price. It has been designed with a graphical user interface that is robust, very simple to learn and is very user friendly. We have upgrade the controls on ICP, RIE, RIE-PE, PECVD, and RF & Microwave Ashing systems. We have done this on many of the OEM dry etch systems out on the market.